Hi all,

Well as I mentioned I decided to replace the wheel bearings before I go about replacing the wheel carriers on my C2 with the Turbo ones. However, the PIA thing about doing the job is getting it done 100% correctly and that involves special tools and heating them just right.

Although I’m not scared of doing the job, I do lack a torch and some of the puller tools handy so I’m going to pass this one off to a local independent shop I use called Scan Automotive. They’ve done great work on my car in the past for things I couldn’t handle so I’m sure they will get these just right as well.

For anyone that is looking to do this, there was a DIY posted on Renntech that I’ll put up here for the sake of having all the information in one place. This is a bit of a risky DIY, so please take it as information purposes only.

Cheers

Aaron

————–

Now let me say that this job was quite straightfoward, BUT I would suggest that you have a bit of experience in bearing fittting as well as presswork or you may really mess things up in a big way. You also need a ball joint service puller set, and yes you need ALL the tools in the kit.

I got mine from OTC/ msc industrial supply cat #78453842. You will also need a way to make some mandrels for pressing the bearings in and out. And a way to heat the carrier to around 150 degrees.

Now for the fun

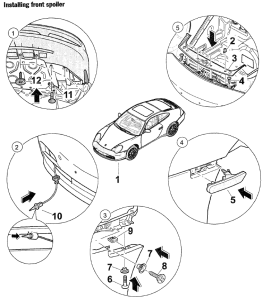

1) jack up car and place on jackstands, remove front wheels

2) remove front plastic underpanel

3) have someone hold the brakes (hard) and remove the front large (1.25″) axel nut, this is TIGHT 340 ft.lbs. so get ready for a fight.

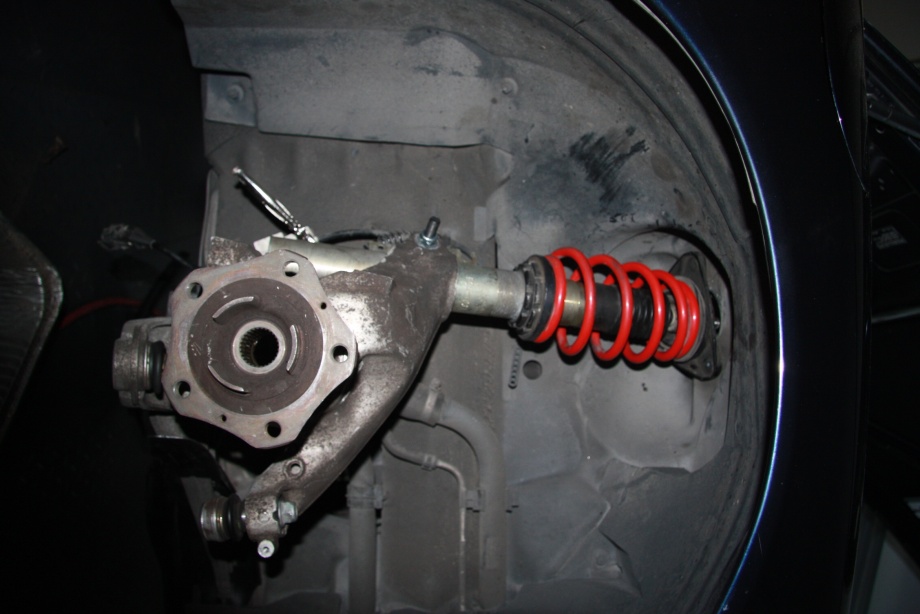

4) with a brass or aluminium mandrel and a hammer tap, (ok smack), the drive shaft to dislodge it from the splines of the hub (don’t mess up the threads!!!)

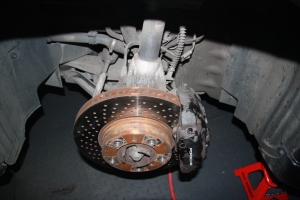

5)Remove the brake pads and the brake caliper (hex drive) tie it up in the wheel well out of the way

6)Remove the psm sensor, move it to the side (2 10mm nuts)

7)unbolt lower sway bar link

8)unbolt headlight sensor link

9)Remove the brake rotor

10) Remove tin brake shield (10mm bolts)

11) remove 18mm nut and press apart tie rod link with the tool

12) remove the 18mm nut and carefully use the tool to press apart the lower ball joint

13) Unbolt the clamp on the strut, then while pressing down on the lower arm slide the carrier off the strut and the front axel (gt2 remove axel-bearing retainer) and take to the bench

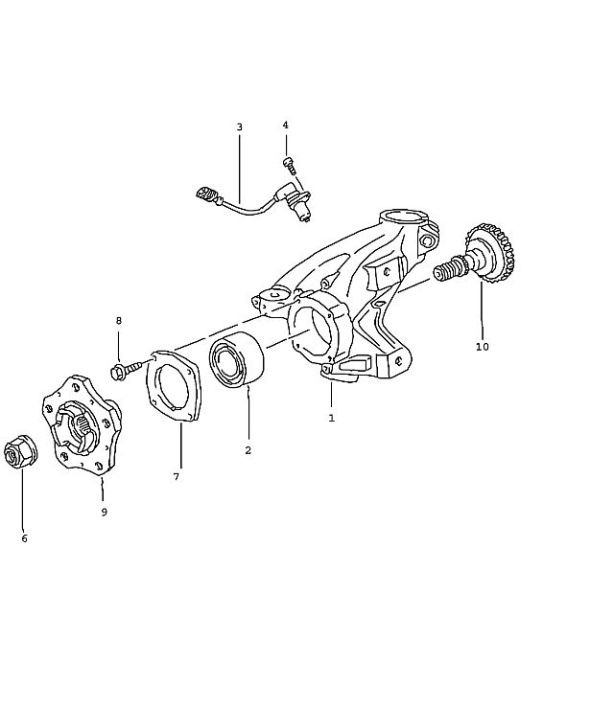

14) Now from the rear side carefully press the center hub out of the bearing, It will come apart with 1/2 the bearing attached to the center hub, it is TIGHT

and will take a bit of force to remove it. Be careful NOT to hurt the carrier as it is $$$ if you break it

15) With a puller remove the center race(the part that was left on the shaft) from the hub, set aside

16) take off the 4- 13mm bolts and remove the bearing retainer plate from the carrier

17) HEAT (and DO NOT skip this step) the carrier to 100 deg,F and with a mandrel press/drive out the bearing from the carrier, again BE CAREFUL when suporting the carrier!!!!

18) Clean all parts.

19) Now the bearing is about a .0035 PRESS fit in the carrier, you CANNOT just press it in cold, you MUST heat the carrier to get it in, there are 2 methods to do this

- heat carrier to 100 deg F and using a mandrell that touches only the outer part of the bearing press in the new bearing

- set a inside micrometer to .004 over the bearing size, then heat the carrier to around 150 deg F, at this point check size with the mike to make SURE the carrier is over the size of the bearing and drop the bearing into the carrier, it will slip right in with no force at all, HOWEVER if you goof up and it sticks 1/2 way you are screwed.

20) Replace the bearing retainer plate with the 4 bolts, if yours has it the small notch goes to the bottom, its a water drain, torque the bolts, 27 ft lbs

21) Very carefully suporting the inner bearing race only,press in the wheel hub to the stop, be careful not to hurt your new bearing. WATCH what you press on!!!!!

22) assemble in reverse order, center 1.25 nut torques to 340 ft,lbs.

23) make sure to torque all bolts/nut to the correct values and double check all bolts.nuts before driving

As you can see this bearing was SHOT, 26,000 miles and sounded like road noise, it did not respond to any tests like a bad bearing at all, so check your bearings!!! Thanks to Jeremy at Imagine Auto for the quick service and the tips, you guys are great !!

Good luck !! Do this repair at your own risk, this diy is just provided as a general guide.